광학

계측

물리적 및 광학적 사양을 포함하여 광학 또는 광기계 제품에 대해 정의할 수 있는 매개변수는 얼마든지 많습니다. 하지만 명시해 주시면 측정해 드립니다.

집중적인 계측을 통해 귀하의 제품이 완벽하게 맞고 모든 광학 사양을 충족하도록 보장합니다. 우리는 코팅이 모든 파장에서 올바른 성능을 제공하는지 확인하고 귀하가 지정하는 곳 어디에서나 LIDT를 측정합니다. 그리고 우리는 모든 광기계 어셈블리의 정렬을 측정합니다.

주요 기능

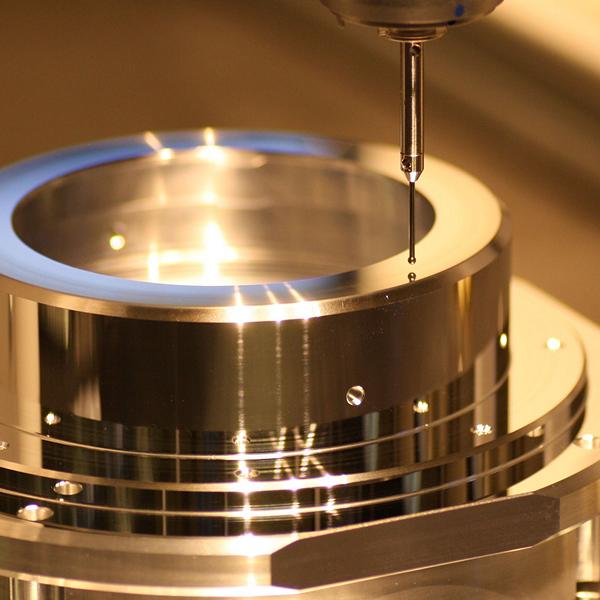

물리적 치수 간단하지만 매우 중요합니다. 우리는 캘리퍼와 같은 검증된 도구를 사용하여 지정된 모든 치수 세부 사항을 측정합니다. |

표면 모양 레이저 간섭계는 반사율이 높거나 투과율이 높은 광학 장치의 모양 정확도(즉, 파면)를 확인하는 데 사용됩니다. |

레이저 유발 손상 임계값(LIDT) 레이저 손상의 임계값을 결정하면 고출력 레이저를 사용할 때 광학 장치가 손상될 가능성이 최소화됩니다. |

분광광도법 대부분의 코팅 성능은 입사광의 파장에 따라 달라지며 우리는 분광 광도계를 사용하여 이를 측정합니다. |

|

표면 매끄러움 원치 않는 표면 거칠기는 산란 문제를 일으킬 수 있으므로 보정된 프로파일로미터를 사용하여 표면 거칠기(Ra)를 정량화합니다. |

광학 제조 기능

|

어셈블리 성능이 보장된 정밀 정렬 어셈블리를 사용하여 시스템 문제를 단순화하십시오. |

코팅 완전한 범위의 코팅 방법을 사용하면 모든 유형의 코팅을 최적으로 생성할 수 있습니다. |

제작 다양한 바카라 카지노 Laser FrameWork 머신 비전 소프트웨어 도구를 활용하여 생산 속도를 높이고 오류를 줄이며 추적성 데이터 제공 등을 수행하세요. |

|

재료 자체 특수 광학 재료를 자체 생산하여 잠재적인 품질 및 공급망 문제를 제거합니다. |

품질 보증 집중적이고 포괄적인 QA 프로그램은 모든 광학 제품이 예외 없이 완벽하게 검사됨을 의미합니다. |

추천 블로그

바카라 카지노 및 NIF: 핵융합 에너지원 생성

바카라 카지노 맞춤형 광학 장치는 태양에 전력을 공급하는 과정인 핵융합을 생성하는 데 사용되는 거대한 레이저 시스템의 일부일 뿐입니다.