AN >654_word_end<->640_word_end698_word_end< AT 3D SENS>654_word_end

>1757_word_end<

>1759_word_end< >1760_word_end<

>1757_word_end<

>1759_word_end< >1760_word_end<

>1784_word_end<

>1785_word_end<

>1787_word_end<

>1788_word_end<

>1789_word_end<

>1790_word_end<

>1799_word_end<

>1803_word_end<

>1804_word_end<

>1805_word_end<

>1806_word_end<

>1815_word_end<

>1819_word_end<

>1820_word_end<

>1821_word_end<

>1822_word_end<

>1823_word_end<

>1824_word_end<

>1825_word_end<

>1006_word_end< for Better >1787_word_end<

>1828_word_end<

>1829_word_end<

>1830_word_end<

>1831_word_end<

>1832_word_end<

>1833_word_end<

>1760_word_end< Shines in 3D Sensing

>1760_word_end< is the world leader in illumination sources for 3D sensing – we’ve shipped over 2 billion units! Our portfolio includes lasers, optics>1841_word_end< complete illumination modules.

>1837_word_end< >1838_word_end<, >1840_word_end<>1841_word_end< >1842_word_end<.

In particular, >1840_word_end< – typically with output at 940 nm – have become the dominant light source for 3D sensing today. There are several reasons for this. One is that the light exits a VCSEL from the top of the device, rather than from the side like in an EEL. This makes it easier to integrate them on a circuit board with other components. Also, VCSELs cost less than EELs at the power levels used in 3D sensing. As a result, EELs are typically only employed at longer wavelengths (1200 nm) where VCSELs with good performance are not yet available. The key advantage of these longer wavelengths is more robust performance in bright sunlight (they allow virtually all sunlight to be filtered out) and enhanced eye safety (10X higher power levels are possible compared near-IR wavelengths).

>1760_word_end< has a mature platform for VCSEL and EEL fabrication based on 6-inch GaAs wafers. This has enabled us to become the volume leader in this technology and to consistently deliver devices with outstanding reliability and performance.

>1846_word_end< >1847_word_end< or pattern projectors. Flood illuminators provide homogeneous light coverage over a specific angle. They are used in applications like facial recognition and gesture detection where uniform light distribution over the entire field of view is key to measurement accuracy.

Pattern projectors are actually used for both triangulation and ToF systems. Combining light patterns with ToF measurements improves signal-to-noise ratio and reduces multipath-induced measurement errors. These are inaccuracies that occur when the light bounces off more than one surface before reaching the sensor.

In each case, optics are used to shape and transform the laser output to meet the exact requirements of the application. Producing a flood illuminator can usually be accomplished with relatively simple, low-cost, molded plastic lenses. But the demands for structured light sources are more stringent.

>1760_word_end< meets the needs for structured light illumination with diffractive optical elements (DOEs) and meta-optics. The latter utilize nanostructures – physical features that are smaller than the wavelength of the light – to alter its propagation properties. This can include changing the beam shape, divergence angle>1841_word_end< intensity distribution, as well as splitting the beam to create structured light patterns.

One great thing about >1760_word_end< meta-optics is that they can combine multiple optical functions – like beam collimation and splitting – into a single compact element. Doing this reduces the size and complexity of the optical system and also improves the overall performance of the 3D sensing module.

Another key differentiator for >1760_word_end< is our ability to engineer and vertically integrate an entire illumination module solution. This integration ensures that the light source, optics, driver IC and packaging are all optimized to work seamlessly together, providing our customers with a reliable, high-performance, yet cost-effective product that is ready for mass deployment in the most demanding applications.

>1760_word_end< manufactures flood illumination and dot projection modules.

For example, our illumination modules for 3D sensing are engineered to minimize electronic parasitics (unwanted capacitance, inductance, or resistance). This is essential for delivering the nanosecond pulse width and sub-nanosecond rise/fall times on which high-accuracy ToF sensors depend. Additionally, we emphasize the importance of eye safety, integrating features that monitor the integrity of the device and the output power to ensure that light output always stays within established safe levels under all circumstances. This is imperative for consumer devices.

When you put it all together, >1760_word_end< provides more than just superior components: You get a team who understands the intricacies of 3D sensing technology and can deliver a complete, integrated solution that enhances device performance and ensures user safety. By partnering with us, you can rely on our legacy of excellence and our continuing development of photonic innovations.

Learn more about >1760_word_end< products for 3D sensing.

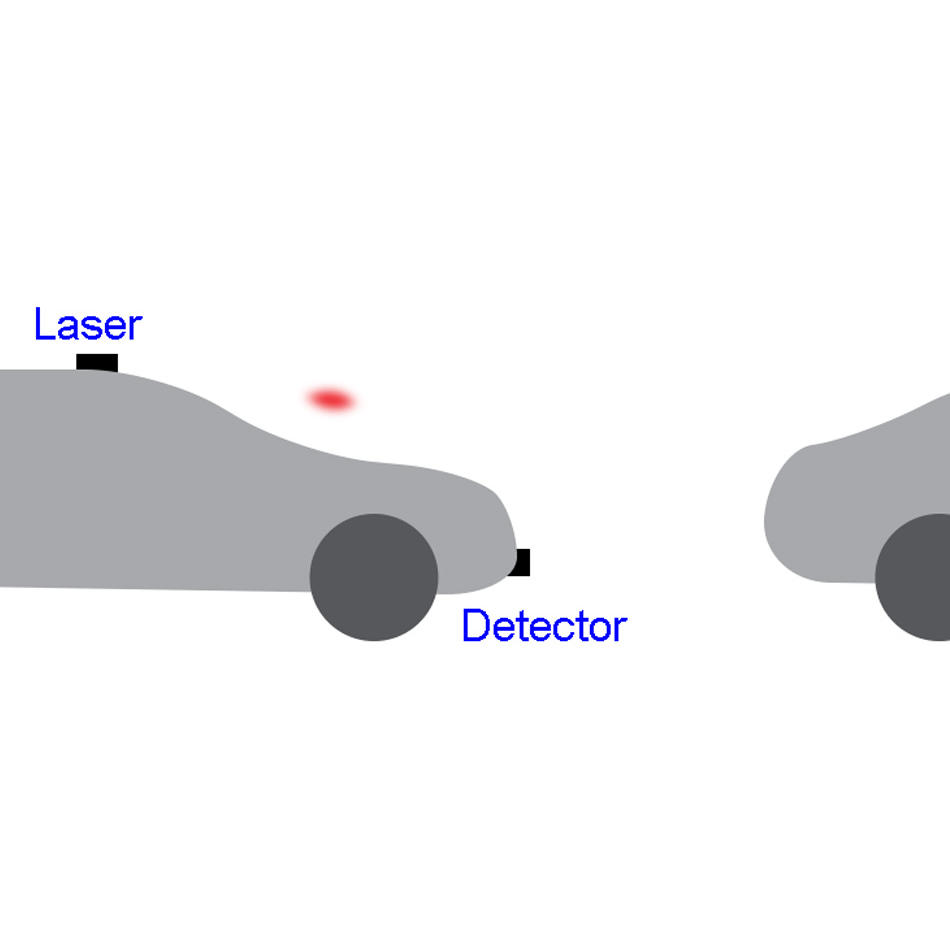

650_word_end<>632_word_end< Measures Position and Speed Remotely"/>

650_word_end<>632_word_end< Measures Position and Speed Remotely"/>